International designer and manufacturer of ultrasonic cleaning machines for almost 40 years. Since 1981, FISA Group has specialized in R&D, laundry processes and water treatment systems.

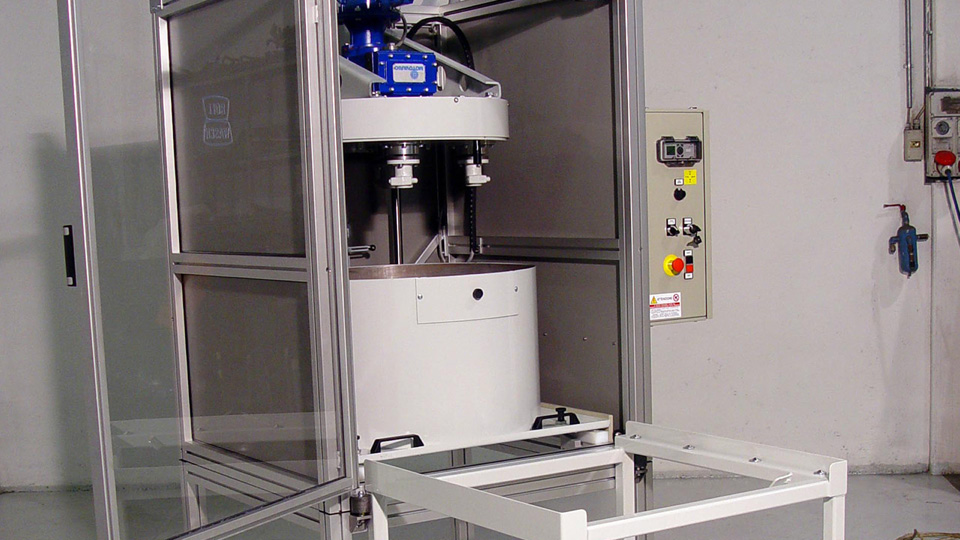

The FISA group offers ranges of machines and “turnkey” solutions perfectly suited to identified markets, in order to provide its customers with a high degree of added value and technology, as well as control of operating costs.

FISA is an international group that was born and raised in Europe, but now also established in North America and Asia, which allows it to offer identical equipment and services to local customers as well as to large multinational companies.

Our technical and commercial teams are at your disposal anywhere in the world to study and solve your ultrasonic cleaning needs and then install and receive the defined equipment.

In a context where the multiplication of subcontractors, the lack of responsiveness, the lack of capacity to adapt to your needs can make your projects risky, FISA controls internally the entire industrial process from design to implementation. production, guaranteeing you strict compliance with your requirements in terms of cost, time and functionality.

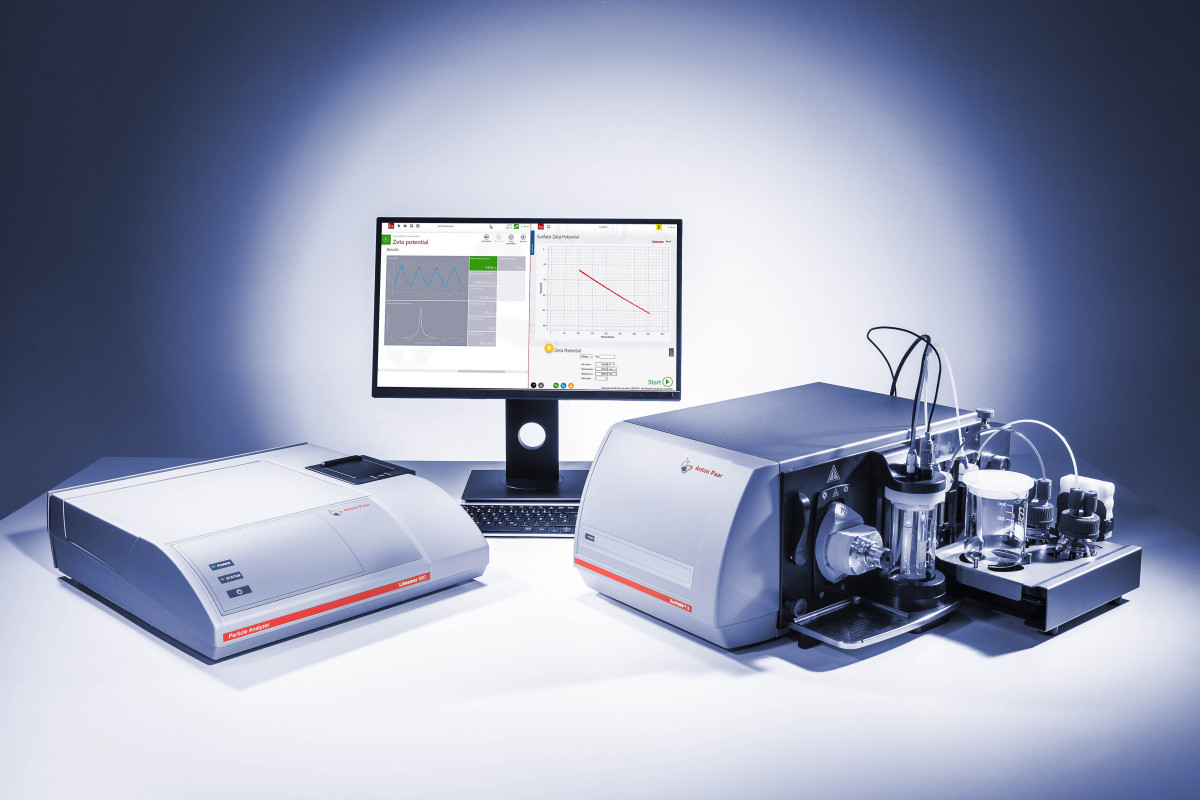

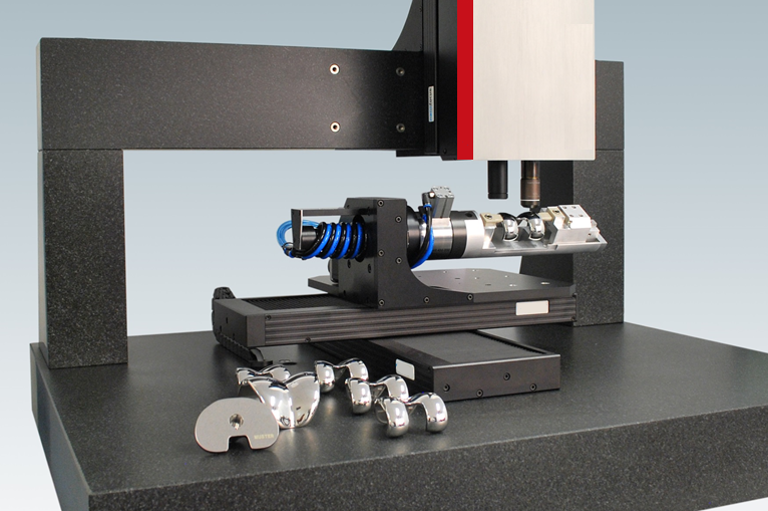

The FISA group puts its application laboratories, some of which have clean rooms, as close as possible to customers within our various entities and at your disposal, to provide you with proof of the results you will obtain.

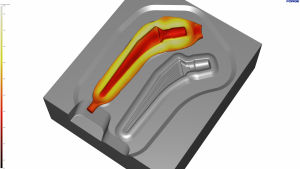

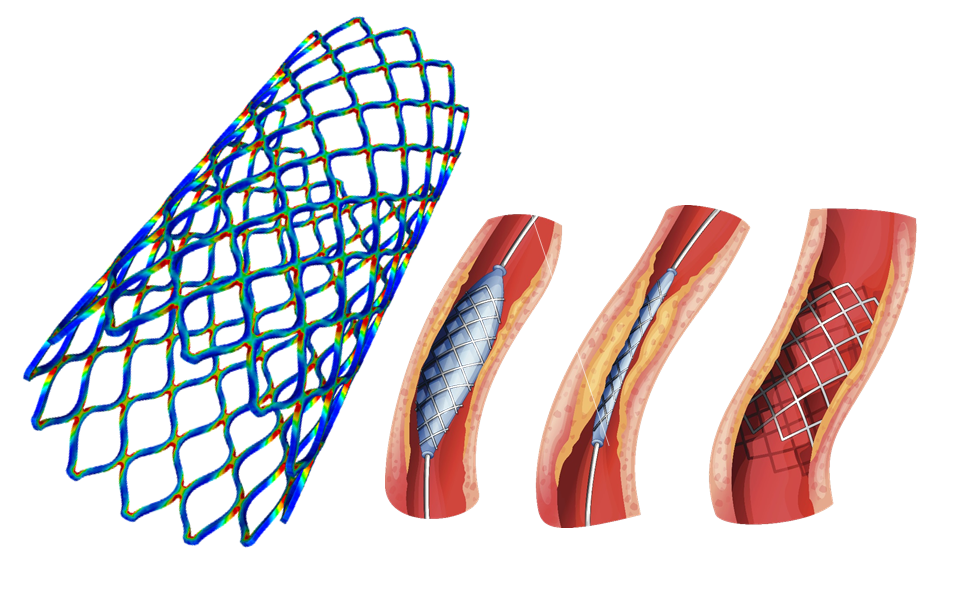

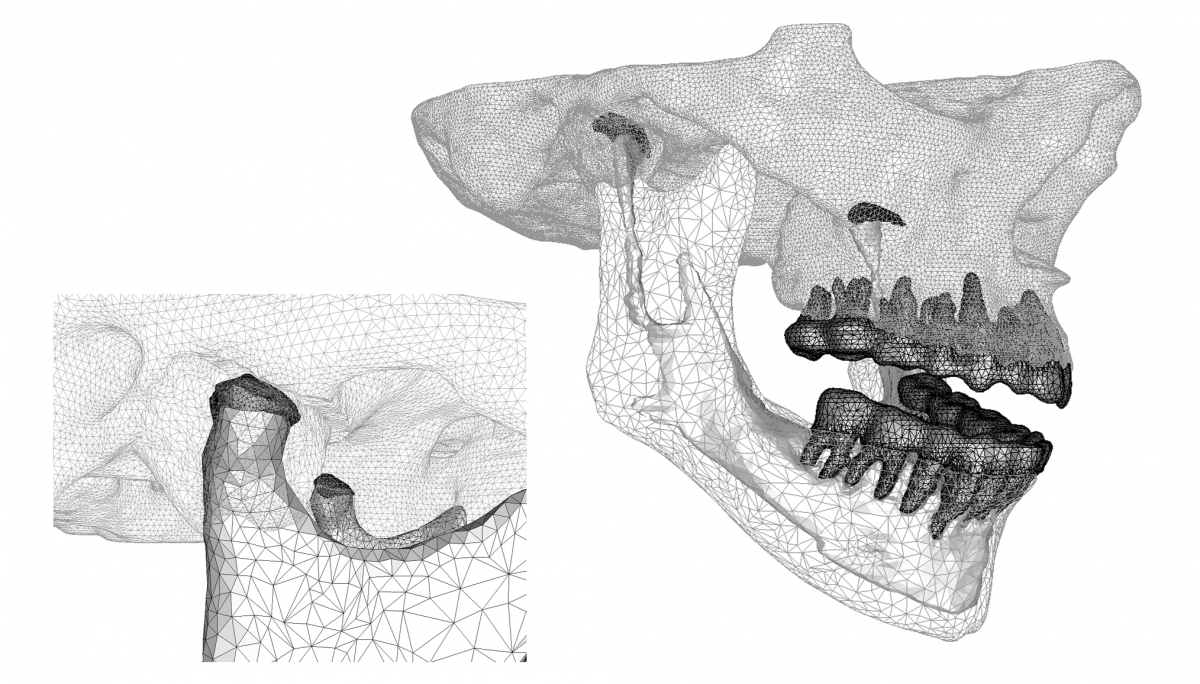

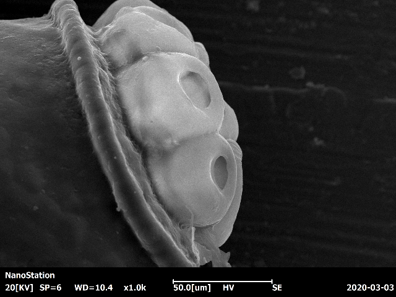

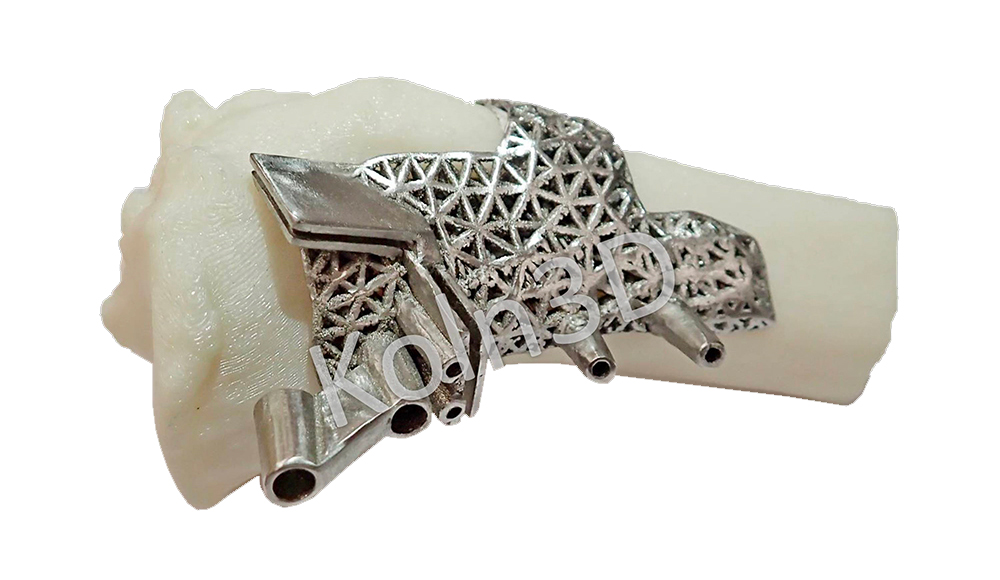

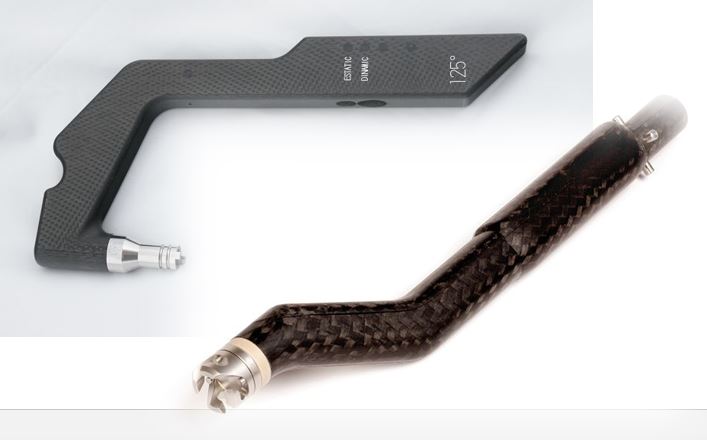

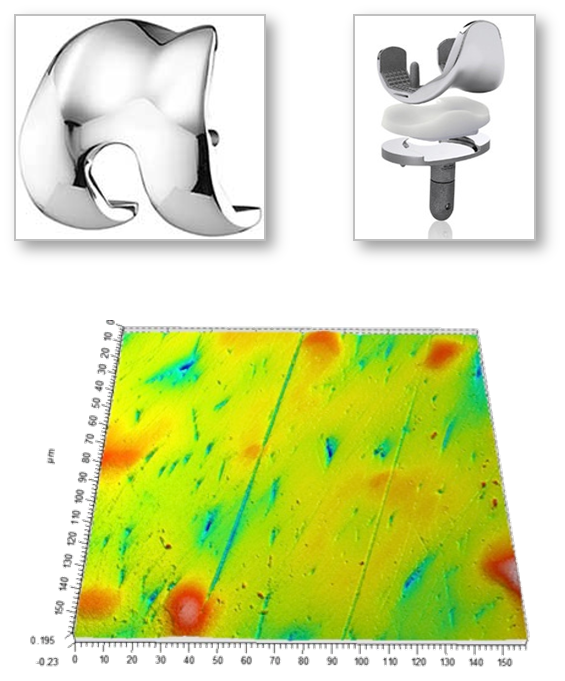

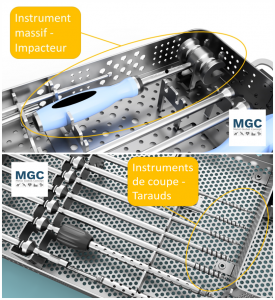

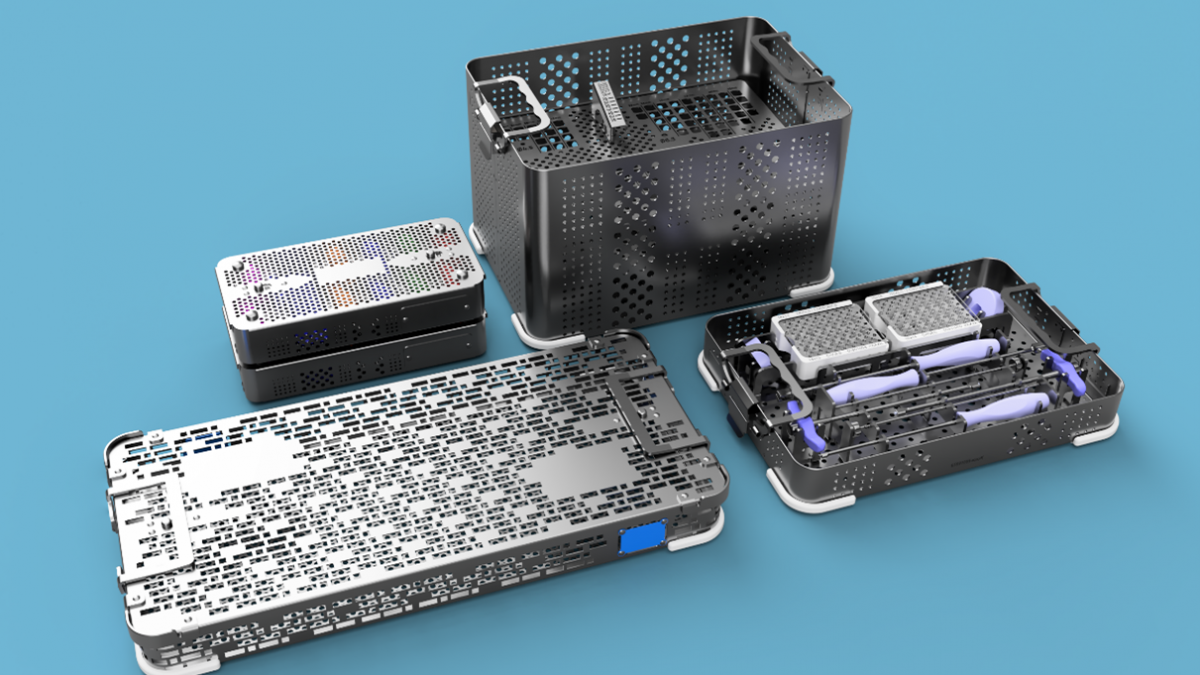

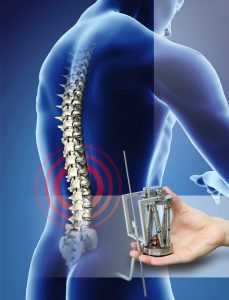

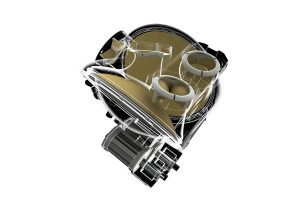

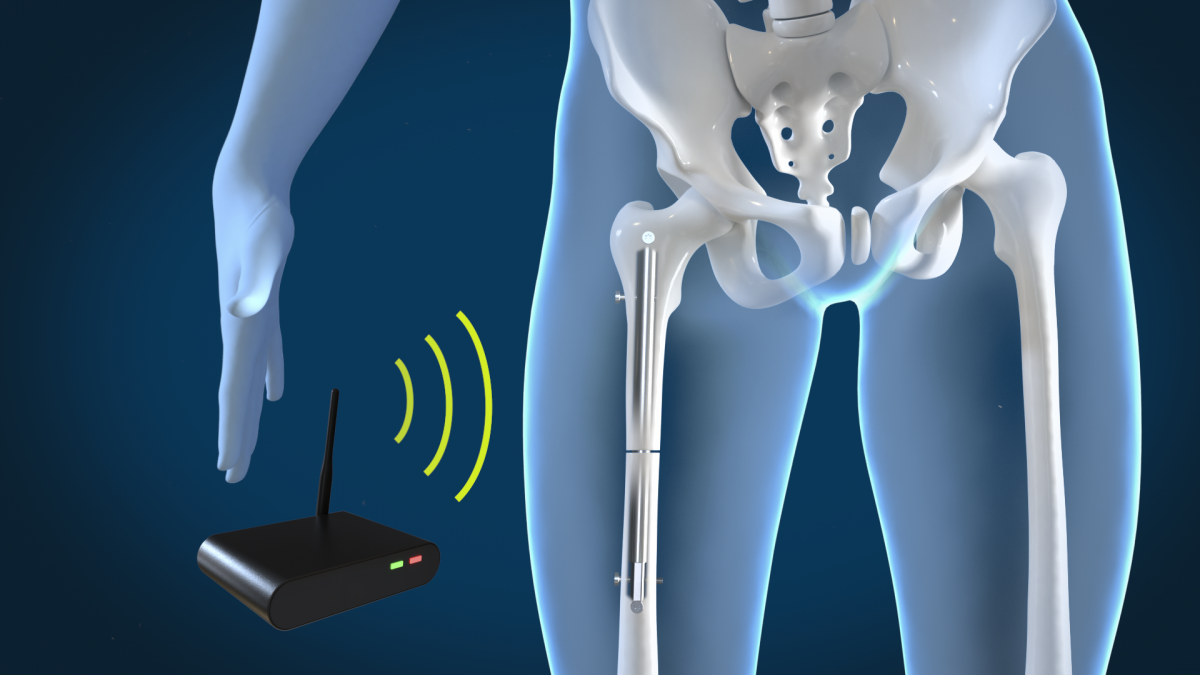

You are manufacturers of implants (hips, shoulders, knees, femurs, pacemakers, stents, oculars, parietals, cochlear, etc.), ancillaries, tools necessary for the placement of implants (probes, burs , drills, cranks, screwdrivers, retractors, hammers, etc.), hypodermic needles, syringes, etc.

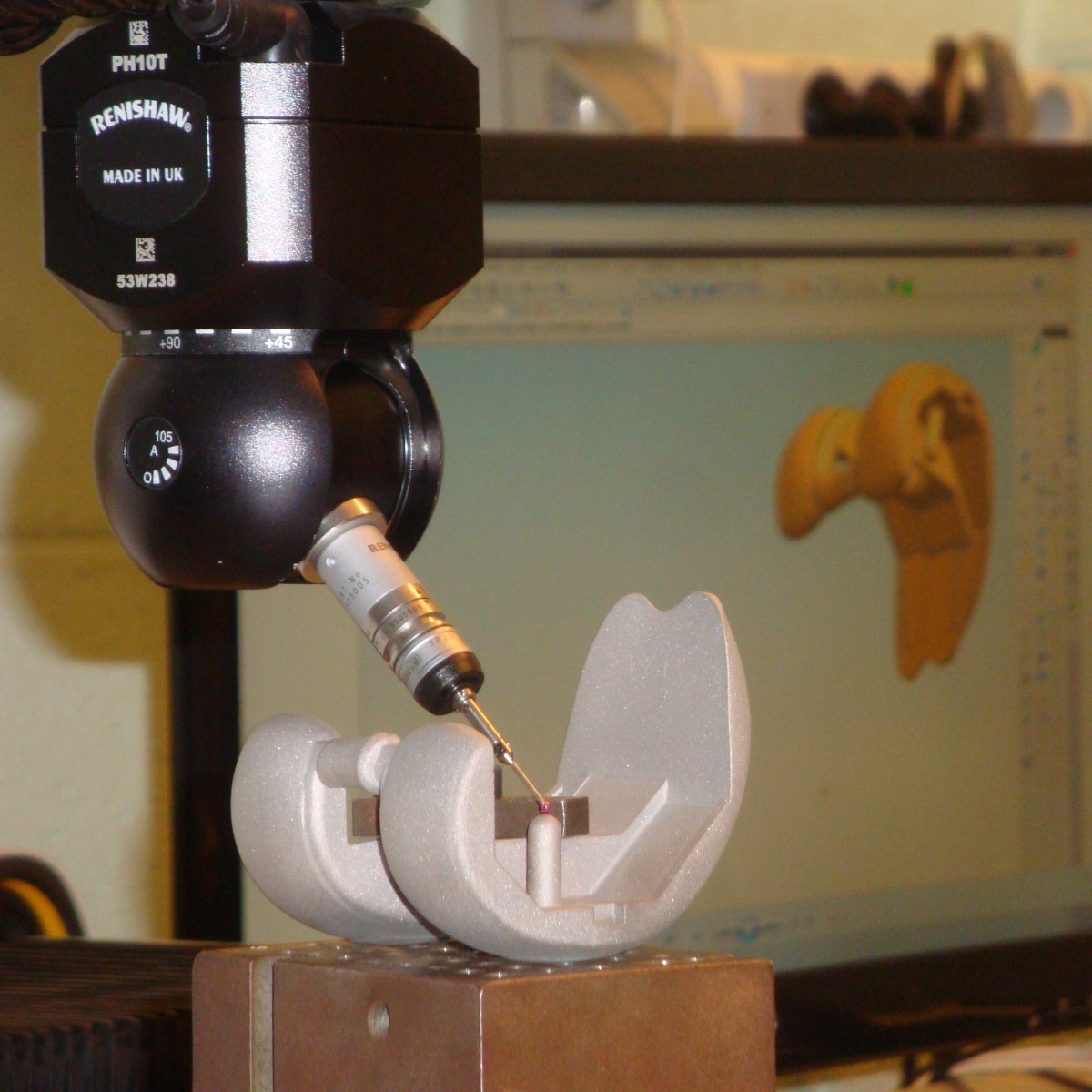

– inter-operation cleaning (elimination of polishing paste, degreasing, elimination of penetrant products, etc.),

– cleaning before or after PAH,

– cleaning before final conditioning on metal or plastic parts,

– decontamination before sterilization,

– passivation of stainless steel parts, Chrome-cobalt, etc.

Our know-how meets all of these requirements in compliance with standards and validation of installations according to QI / QO / QP qualification protocols.

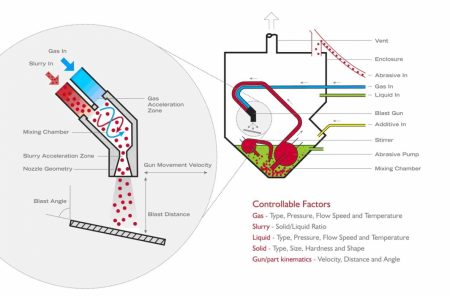

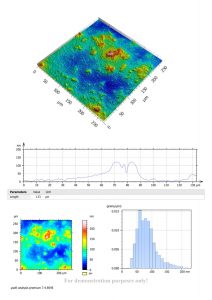

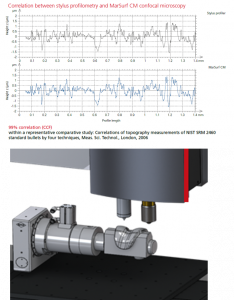

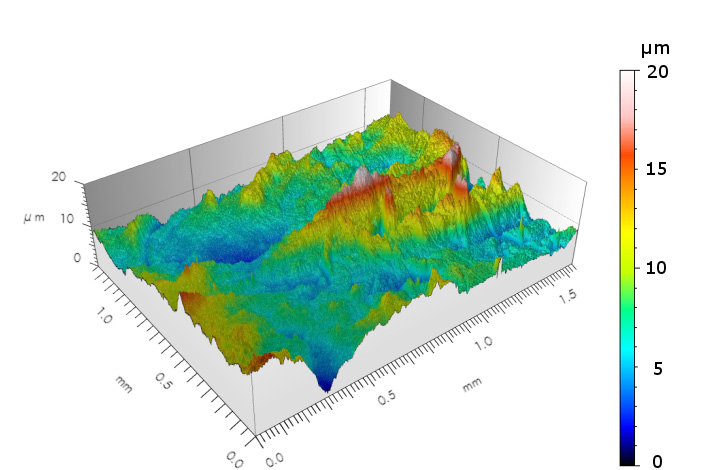

Our process control allows us to define the water treatment system adapted to your needs (production of demineralized water according to your qualitative grade) and of course the washing process which will precisely meet your specifications.

We also integrate into our equipment, secure solutions for surface treatment processes such as etching, anodizing or electro-polishing.

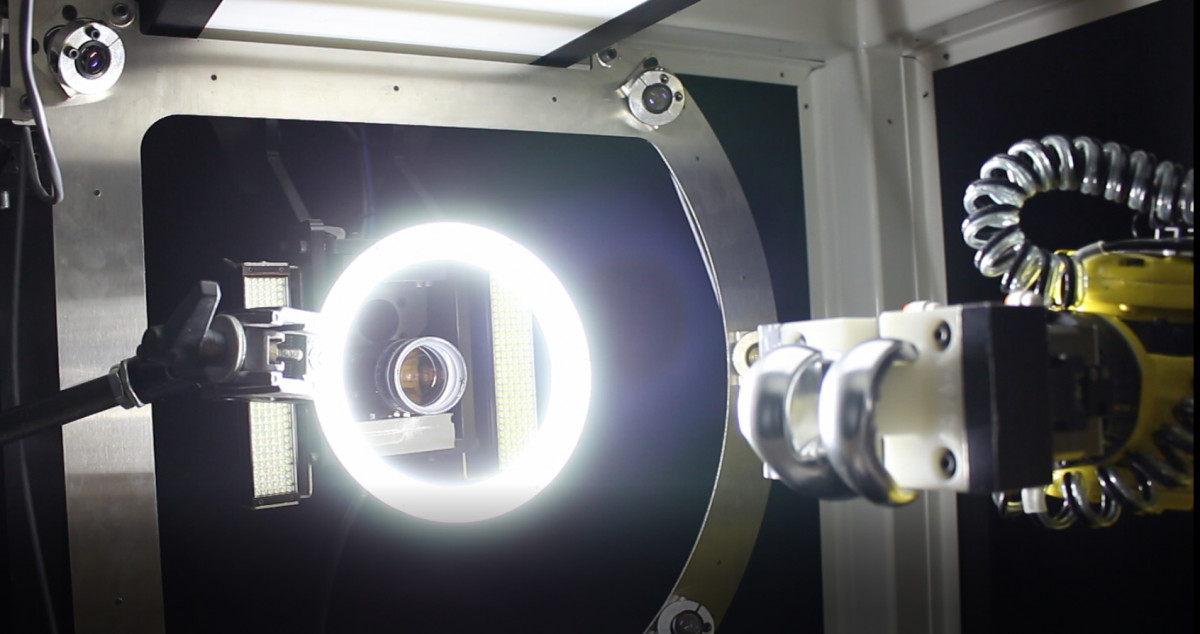

Finally, with our new touchscreen human-machine interface, the MCU and its associated plugins, you will have a simple and user-friendly tool, easily configurable, fitting perfectly into a production 4.0 environment by integrating automation solutions such as COBOT, AGV.

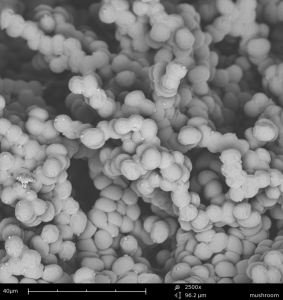

Steiger Galvanotechnique SA in Châtel-St-Denis (CH) is a member of the Estoppey-Reber group founded in 1885 and employs 160 people. The other members of the group, Estoppey-Reber SA, Akrom SA and Galvametal SA are located in Aegerten. The four companies are active in electrochemical and chemical surface treatments and are positioned as international leaders in the galvanotechnical industry.

Steiger Galvanotechnique SA in Châtel-St-Denis (CH) is a member of the Estoppey-Reber group founded in 1885 and employs 160 people. The other members of the group, Estoppey-Reber SA, Akrom SA and Galvametal SA are located in Aegerten. The four companies are active in electrochemical and chemical surface treatments and are positioned as international leaders in the galvanotechnical industry.